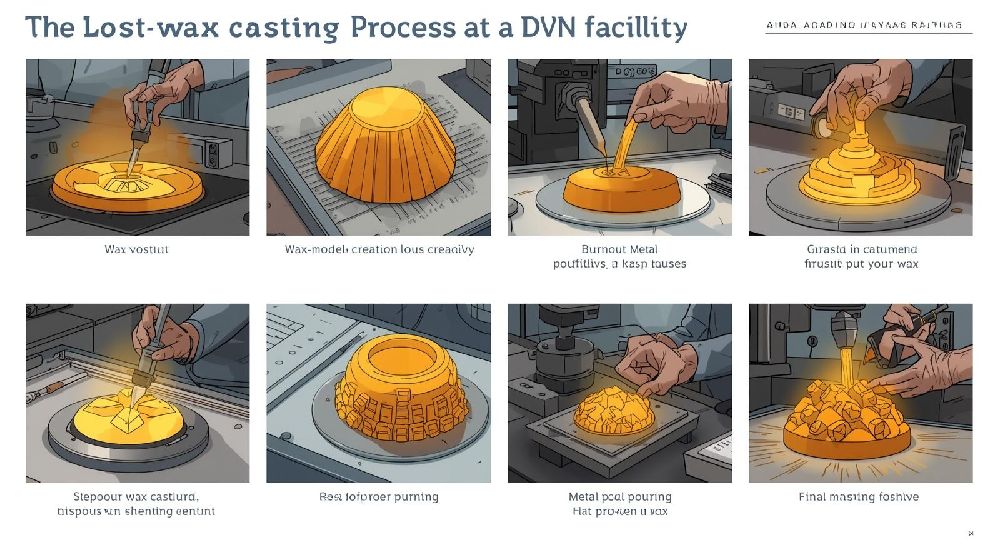

Lost-wax casting is one of the oldest and most trusted techniques in jewelry manufacturing. At DVN Jewelry, this traditional art meets modern precision to create gold pieces that are flawless, detailed, and beautifully crafted. Whether it’s an intricate ring, a textured pendant, or a designer bangle, lost-wax casting is the foundation of many DVN masterpieces.

Here’s an inside look at how DVN transforms a simple piece of wax into a stunning piece of gold—from Wax to Wonder.

1. Designing the Jewelry: Where Creativity Begins

Before the casting process starts, DVN’s design team creates a precise CAD model of the jewelry piece.

This digital blueprint defines:

-

Dimensions

-

Thickness

-

Details

-

Textures

-

Stone settings

The CAD model ensures accuracy and guarantees that the final cast matches the original vision perfectly.

2. Wax Model Creation: Bringing the Design to Life

Once the design is finalized, a wax replica of the jewelry is produced using:

-

Wax injection machines

-

3D printing

-

Hand-crafted detailing (for special pieces)

This wax model is an exact copy of the final jewelry piece in every detail.

At DVN, this step is essential because the quality of the wax determines the quality of the gold casting.

3. Tree Assembly: Organizing the Wax Models

Multiple wax models are attached to a central wax rod, forming what is known as a wax tree.

DVN ensures:

-

Clean joint formation

-

Proper spacing

-

Balanced arrangement

A well-made wax tree allows molten gold to flow smoothly during casting, preventing defects or air pockets.

4. Investment Molding: Preparing for Casting

The wax tree is placed inside a metal flask and filled with a fine plaster-like material called investment slurry.

Once it hardens, it forms a heat-resistant mold.

During this stage DVN uses:

-

High-quality investment powder

-

Controlled vacuum investment

-

Proper dry time

This ensures a flawless mold with fine detailing captured accurately.

5. Wax Burnout: Creating the Hollow Cavity

The flask is heated in a burnout furnace, where the wax melts away and evaporates completely.

This step:

-

Removes every trace of wax

-

Leaves a perfect hollow cavity

-

Prepares the mold for molten gold

-

Enhances detail accuracy

This is why the technique is called “lost-wax”—the wax is lost, leaving only the mold behind.

6. Gold Melting & Casting: Transforming Metal into Art

DVN uses electric induction melting machines to heat gold to the perfect temperature.

Once molten, the gold is poured or vacuum-cast into the mold.

This stage ensures:

-

Smooth metal flow

-

Zero shrinkage defects

-

Strong structure

-

High surface accuracy

DVN maintains strict temperature control to guarantee casting consistency and high purity.

7. Cooling & Breaking the Mold: Revealing the Raw Design

After the gold solidifies, the investment mold is broken apart to reveal the cast jewelry pieces.

This moment is where wax becomes wonder—the first raw glimpse of the final product.

DVN ensures gentle handling to protect intricate details and shapes.

8. Cutting, Filing & Smoothing: Refining the Structure

The cast pieces are cut off from the tree, and the surface is cleaned through:

-

Filing

-

Grinding

-

Sanding

-

Smoothing

This removes rough edges, excess metal, and casting marks.

DVN artisans shape the piece with precision to prepare it for the final finishing stages.

9. Polishing & Finishing: From Raw to Radiant

The jewelry then goes through multiple polishing stages:

-

Emery polishing

-

Buff polishing

-

Mirror finishing

-

Micro-polishing

Finishing enhances shine, smoothness, and overall beauty.

DVN uses advanced polishing machines to deliver a premium, glossy, showroom-ready look.

10. Stone Setting & Final Touches

If the piece includes stones, this is where DVN’s expert setters take over.

They ensure:

-

Perfect alignment

-

Tight, secure fitting

-

Clean finishing around stones

Finally, the jewelry goes through quality inspection for purity, strength, and detailing.

Conclusion

Lost-wax casting is a beautiful blend of tradition and technology. At DVN Jewelry, it transforms simple wax models into flawless gold creations using:

-

Expert design

-

High-quality materials

-

Precision engineering

-

Skilled craftsmanship

From a wax idea to a shining wonder—every DVN piece carries the legacy of this ancient technique, refined with modern innovation.