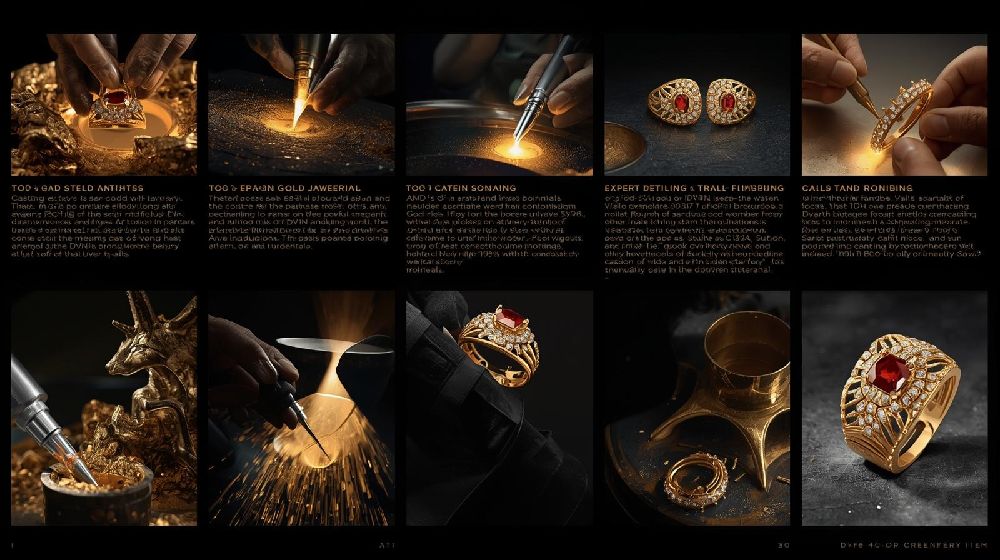

Every gold ornament created at DVN Jewelry carries a story — a story of precision, technology, craftsmanship, and uncompromising quality. The journey from raw gold to a finished masterpiece involves multiple stages, each executed with strict manufacturing standards. This is where DVN stands apart: every step is engineered for perfection.

Every gold ornament created at DVN Jewelry carries a story — a story of precision, technology, craftsmanship, and uncompromising quality. The journey from raw gold to a finished masterpiece involves multiple stages, each executed with strict manufacturing standards. This is where DVN stands apart: every step is engineered for perfection.

Let’s walk through the complete manufacturing journey of a DVN gold piece.

🔶 1. Gold Purification & Alloying – The Foundation of Strength

The journey begins with selecting high-purity gold. DVN uses hallmark-grade purity — 9K, 14K, 18K, or 22K — based on the design.

What DVN Does in This Stage

-

Melts pure gold at controlled temperatures

-

Mixes alloys (copper, silver, zinc) in precise ratios

-

Uses digital weighing and automated alloying machines

-

Ensures strength, color consistency, and durability

This ensures that every piece has the correct karat, accurate weight, and optimal hardness for manufacturing.

🔶 2. Wax Modeling – The Blueprint of the Design

Before gold comes into play, DVN creates wax models using either:

-

CNC milling

-

3D printing

-

Hand carving (for traditional designs)

Why This Stage Matters

Wax defines the final design. Every curve, edge, and detail is set here. DVN’s computerized modeling ensures:

-

Symmetry

-

Lightweight precision

-

Perfect reproduction of intricate designs

🔶 3. Investment & Casting – Turning Wax into Gold

This is where the real transformation happens.

DVN Casting Process

-

Wax models are attached to a base to form a “tree.”

-

The tree is placed into a cylindrical flask.

-

Investment plaster fills the flask and hardens around the wax.

-

The flask is heated — the wax melts away (lost-wax casting).

-

Molten gold is poured into the cavity.

Why DVN’s Casting Stands Out

-

Vacuum casting avoids air bubbles

-

Controlled temperature ensures flowability

-

Gold fills even the thinnest sections

-

Smooth surface with minimal defects

Casting at DVN is engineered to ensure structural strength and weight accuracy.

🔶 4. De-Casting & Cleaning – Revealing the Structure

Once the gold solidifies:

-

The plaster mold is broken

-

The gold tree is removed

-

Individual pieces are cut off

-

The surface is cleaned using ultrasonic technology

This stage ensures the rough casting is ready for refinement.

🔶 5. Filing & Shaping – Perfecting the Form

Now comes the detailed correction work.

DVN’s Process Includes

-

Removing excess metal

-

Softening sharp edges

-

Maintaining symmetry

-

Bringing the design closer to its final form

Artisans use micro-files, carbide tools, and rotary machines to refine each piece. DVN combines human craftsmanship with machine precision to maintain uniformity.

🔶 6. Pre-Polishing – Preparing the Surface

Before any stones are set or final finishing is done, DVN performs pre-polishing.

What Happens Here

-

Rough scratches are removed

-

Surfaces are smoothened

-

Edges are blended

Pre-polishing ensures that the final polish shines evenly and beautifully.

🔶 7. Stone Setting (If Required)

For pieces with CZs or gemstones, expert setters work by hand.

DVN Specializes In

-

Micro-setting

-

Channel setting

-

Prong setting

-

Bezel setting

Using microscopes and laser tools, DVN ensures strong grip and neat alignment.

🔶 8. Laser Welding – Fixing Microscopic Imperfections

Laser welding is used for precision repairs or joining small components.

Why DVN Uses Laser Welding

-

No marks or burns

-

Strong, clean joints

-

Perfect for lightweight jewelry

-

Ideal for hollow or delicate pieces

This ensures durability without compromising beauty.

🔶 9. Final Polishing – The Signature DVN Shine

This is the stage that gives the gold piece its ultimate brilliance.

DVN Uses Multiple Polishing Techniques

-

Machine buffing

-

Hand polishing

-

Soft-wheel polishing

-

Micro-abrasive finishing

Depending on the design, DVN produces finishes such as:

-

Glossy

-

Matte

-

Satin

-

Rhodium plated

This final polish gives every DVN product its premium, retail-ready appearance.

🔶 10. Quality Check – Every Piece Must Pass 10+ Tests

No gold piece leaves DVN without strict QC.

DVN’s Quality Control Includes

-

Weight accuracy

-

Karat purity testing

-

Dimension & symmetry check

-

Surface inspection

-

Stone tightness test

-

Polishing consistency

-

Structural strength test

-

Manufacturing defect scan

Only pieces that pass all checks move to final packaging.

Conclusion

The journey from casting to polishing at DVN Jewelry is not just a manufacturing process — it’s a blend of technology, precision engineering, and skilled artistry. Every DVN gold piece reflects:

-

Strong foundation

-

High-tech production

-

Expert craftsmanship

-

Premium finishing

-

Unmatched quality control

This is why DVN remains a trusted name for jewelers and wholesalers seeking reliable, beautifully crafted gold jewelry.